|

During our technical tests on July 7th on train tracks, the onboard computer recorded data from the different sensors mounted on the train: sun irradiance, voltage and current provided by the solar panels and the position of the wheels. The goal was to determine:

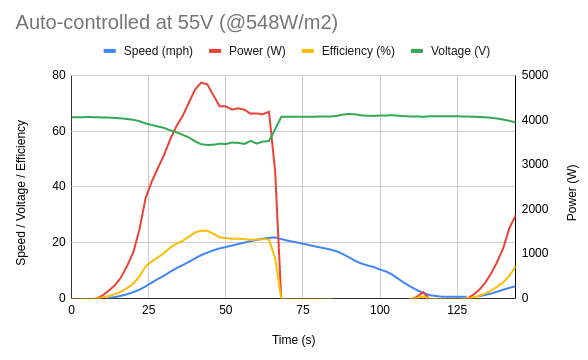

After the tests, we downloaded the data logs and analyzed them in a spreadsheet. Solar panel efficiencyComputing the solar panel efficiency is straightforward: the sun irradiance sensor, positioned at the same angle as the panels, measures how much solar power is received on the panels and the voltage multiplied by the current gives the power the panels are generating. Monocrystalline solar panels are sensitive to the temperature: efficiency decreases with temperature rise. The panels we are using are 22.2% efficient at 25°C but lose 0.29% of efficiency for each additional degree. The peak efficiency is reached when the optimal amount of current is drawn from the panels. The optimal current depends on the sun irradiance and the panel temperature. We estimated the peak efficiency would produce around 55V. We estimated that the solar panels would warm up to 35°C so we expected their efficiency to be around 19.3%. Fig 1: Graph of run #10 data Run #9 test conditions:

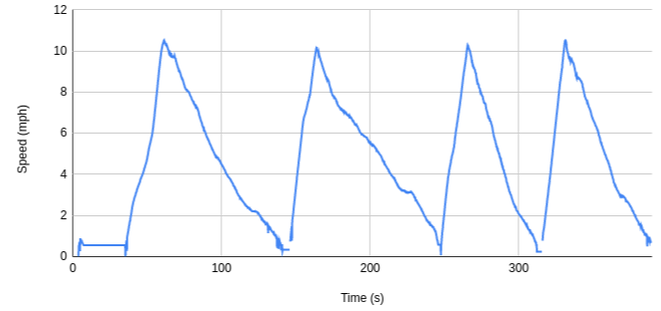

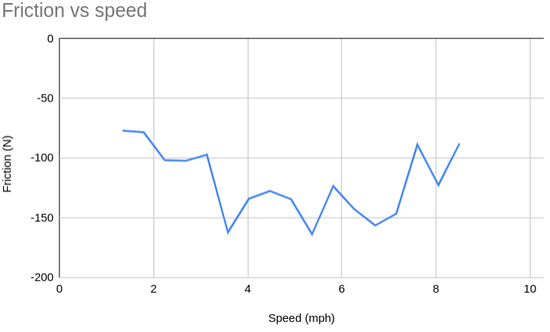

Based on the measurements, the efficiency of the panels is above 21% at 55V under those conditions, which is above what we expected! Rolling friction To determine the friction, we accelerated multiple times the train up to 10 mph and let it slow down to a near stop by itself. By knowing the weight of the train, we know how much energy the system has at 10 mph. The energy loss over time is due only to the friction so we can compute the friction force. Fig 2: Graph of run #8 speed data Test conditions:

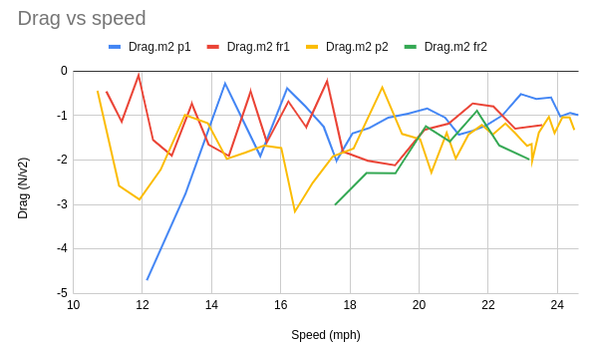

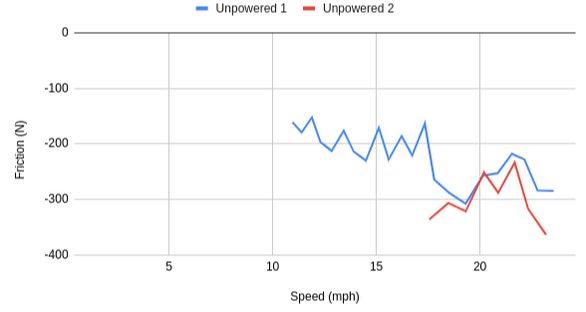

Fig 3: run #8 friction vs speed Since 10 mph is a relative low speed, we can assume that this friction is mostly created by rolling friction. The friction is, as expected, mostly constant regardless of the speed. Based on those measurements, we can assume that our rolling friction is about 125N. This is close to the double of what we expected: we expected the rolling friction to be around 70N. However during this first test, the solar train has its axle misaligned, so we expect the rolling friction to be reduced considerably now that the axles have been aligned correctly. Air friction To determine the air friction, we ran the train at a higher speed and let it slow down. Fig 4: graph of run #9 data Fig 5: graph of run #9 friction We now see that the friction increases with the speed. By subtracting the rolling friction, we can deduce the air friction and compute the drag. The air friction is proportional to the square of the speed.  Fig 6: graph of run #9 drag By dividing the remaining friction by the square of the speed and the frontal surface, we can now see that we have a roughly constant drag coefficient independent of the speed. Based on those measurements, we have a drag coefficient around 1.5. This is quite a large drag coefficient but it was expected: the train has no aerodynamic body during this test. We expect to reduce considerably the drag coefficient after adding the body panels and we will measure the drag again during our next tests. Motor efficiency Now that the friction forces have been estimated, we can measure the motor efficiency by looking at how much electrical power we provide to the motor and how much mechanical power is generated. Our data were not accurate enough to create a graph but we estimated the electric motor to have an overall efficiency of 85%. This is less than expected, we expected above 88% but the maximum efficiency of the motor should be when it reaches 4,000 rpm (when the train runs at 65 mph) so we expected to see a higher efficiency when we test the train at a higher speed. ConclusionThanks to the data logged during the technical tests, we were able to validate that the energy consumption of our solar train is close to our prevision.

This validates our design and we won't do any major revisions following those tests. This also increases our confidence that we can reach 65 mph with the full 80' structure with an aerodynamic body. - Marco

0 Comments

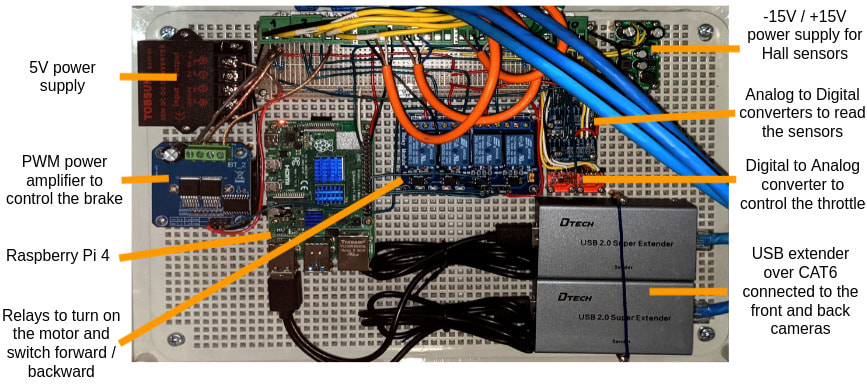

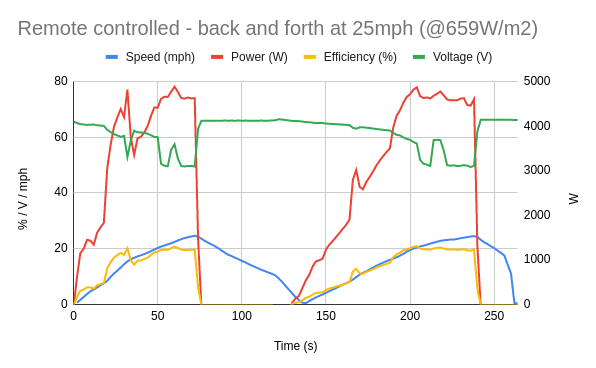

From left to right: Ryan from NWPR, Eric, Marco, Jensen On July 9th and July 10th, we conducted a series of technical tests on Northwestern Pacific Railway tracks next to Sonoma. Our main objective during those tests was to ensure the structural stability of the train. Our secondary objective was to capture data to ensure the accuracy of our top speed estimation. The I-beams used as the backbone for the structure are very flexible and we added multiple X-braces to reinforce the frame. However we were not sure if this was enough or if we would have dangerous oscillations that might cause the train to derail. To test safely, we built a remote control system, so the train can be driven at high speed with no-one onboard. Using a 30’ trailer, we moved the train from the workshop to Shellville Train station, set it up on the rails there and drove south to the test location. Ryan, from NWPR, was the railway expert guiding our team during the test and was driving a Hi-Rail truck to accompany. The solar train number is STX22: ST for Solar Train, X for a car not owned by a railway company, 22 for 22% solar panel efficiency. The first dayJust after the road crossing, the train derailed at the first curve: the spacing of the wheels was not correct (too narrow). Fortunately, we were travelling less than “ludicrous speed” and we were able to change the spacing quickly on-site to re-rail the train. We drove through the rail yard up to the first test location: about 2 miles of straight tracks. We then tested the stability of the structure and verified that the remote control system is working as expected, using an onboard phone to provide the network connectivity. “Kill switches” on each end of the test section were placed on the track to trigger the brake automatically in case we lost control of the train when nobody was onboard. We ran out of time to conduct more tests: the sun was already low in the sky and we had to use our battery pack to go through the shadow of the rail cars parked in the rail yard. The end of the first day: solar train vs oil tankers. The second day That day, we received the authorization to drive outside the rail yard. We decided to drive down to Petaluma River, past Sonoma Raceway, since there is a 4-mile straight section there of welded rails. This is about 10 miles away. Driving south, we kept the speed at 10 mph to ensure that the drivers were safe. So it took about one hour to reach our test location, taking one bridge and crossing one major road (highway 37). After setting up the test section, we ran many technical tests and collected data. We ran the train up to 25 mph (remote controlled) without issue. The sun decided to call it a day before we were ready so we were not able to reach a higher speed on that section of the track. When we drove back, it was already past 6pm. We barely made it through the shadows of trees and hills. When we reached the rail yard, our pack battery was completely discharged so we had to use some muscle to power the train the last mile. End of the second day: the sun is low in the sky ConclusionThe technical tests were successful:

Next step: Add the body panels and test at a higher speed! |

Archives

August 2021

Categories |

RSS Feed

RSS Feed